Lens Edging Solution

Introducing a variety of Huvitz products sold in the global market.

-

Drilling Machine

HDM-8000

Standalone drilling machine that enables simultaneous rimless lens processing and drilling

-

Network Solution

HERA Intraworks

Data transmission software for easily transferring data between Huvitz lens edging systems

Latest Product News

- PRODUCT

24 October 2025

Processing Speed of HPE-990 Proven Through Comparison with HPE-910 The competitiveness

- Press Releases

2025년 May 15일

글로벌 아이케어 전문기업 휴비츠(대표 김현수)가 세계 최초로 렌즈 오버 프레임 선글라스 가공이

Latest SNS News

FAQ

What types of lenses and frames are compatible with Huvitz's lens edging solutions?

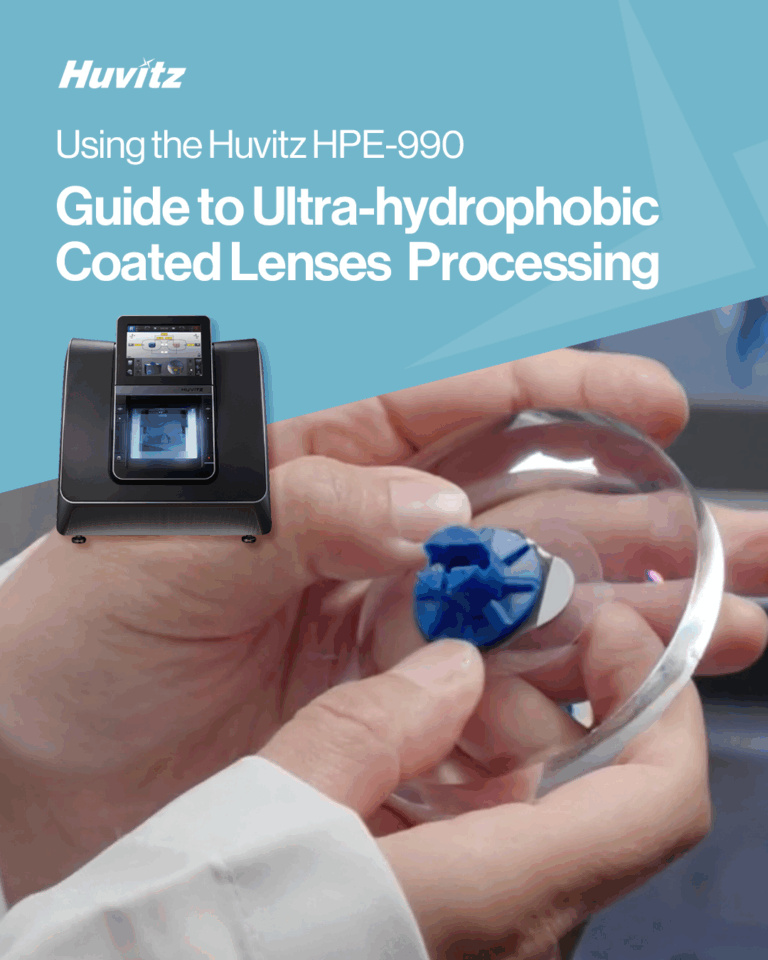

Huvitz lens edging solutions, equipped with a powerful motor wheel and Xtra Large clamp, can reliably process a wide variety of lens materials including standard lenses, high-index lenses, and even super-hydrophobic lenses. Additionally, features like step bevel, scan & cut, and drilling functions make them ideal for processing challenging frame types such as full-frame, half-rim, rimless, sports goggles, and over-the-frame lenses.

Are Huvitz lens edging solutions automated?

Are Huvitz lens edging solutions complicated to use?

Huvitz lens edging solutions are designed with a user-centric interface and intuitive operation system, making them easy for anyone to use. With automated lens processing and features like step bevel, scan & cut, and drilling, users can complete tasks quickly with minimal settings. Comprehensive user manuals, step-by-step training materials, and online tutorials are also available to help new users get up to speed quickly.

What key factors should be considered when adopting a lens edging solution?

How is installation and training handled after purchase?

After purchase, a certified engineer will visit your site to install and configure the equipment based on the specific setup environment. Basic user training is provided to all customers, and additional training or remote support is available upon request.

How is maintenance handled for Huvitz lens edging solutions?

Regular maintenance, such as cleaning, replacing consumables (grinding wheels, water filters, etc.), and software checks, ensures reliable performance. In the event of a malfunction, dedicated support is available via phone consultation, remote assistance, or on-site visits. Based on the urgency and situation, the most appropriate service will be provided, including parts replacement and follow-up inspections if needed.