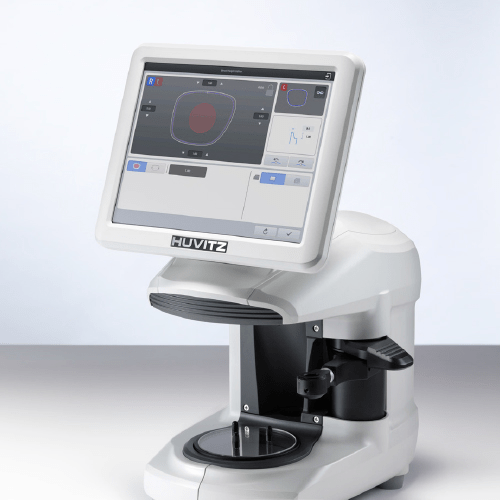

HPE-410

Lens Edger

Standard lens edger with built-in tracer, focusing on essential functions for lens processing

- Stable processing without axis off

- Customized lens processing

- Reduced processing time with built-in tracer

MENU

Explore Details

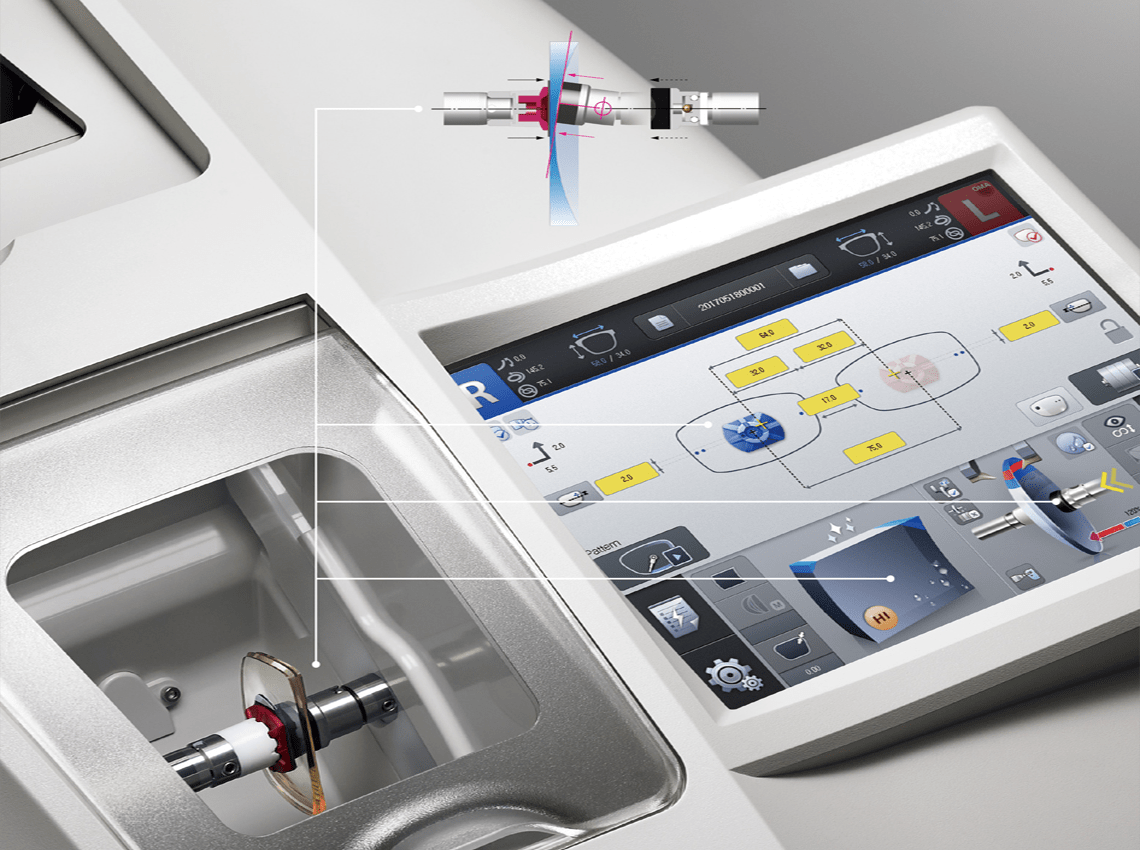

Stable processing without axis off

Adaptive Clamp Chuck, Roughing Method, and Hydrophobic Mode provide stable processing without axis off during lens edging.

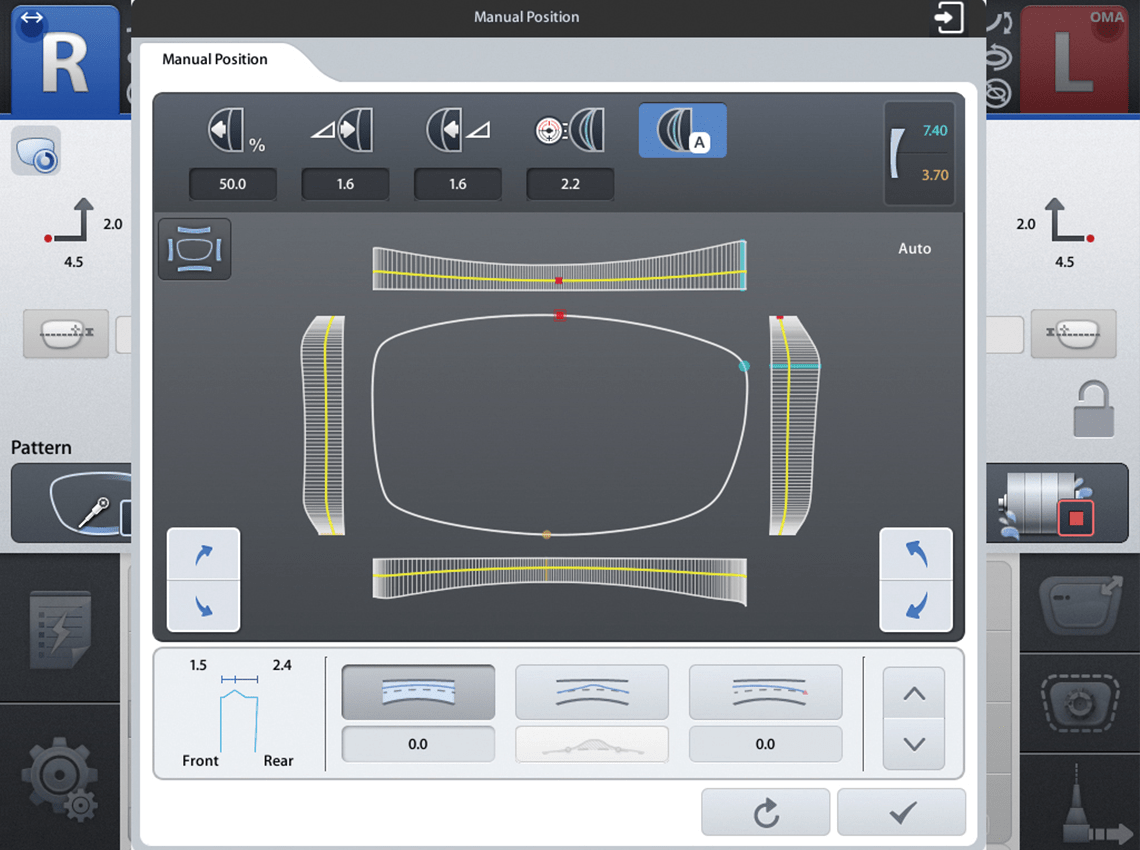

Customized lens processing

Through 2D and 3D simulation applied to 6 types of bevel and 4 types of grooving. Automatic calculations are made according to the lens type, thickness and frame for more accurate processing by selecting the optimal positioning

Basic Bevel : Flat, Normal, Partial, Mini, Concave, Retouch

Grooving : Normal, Partial, Dual, Hybrid

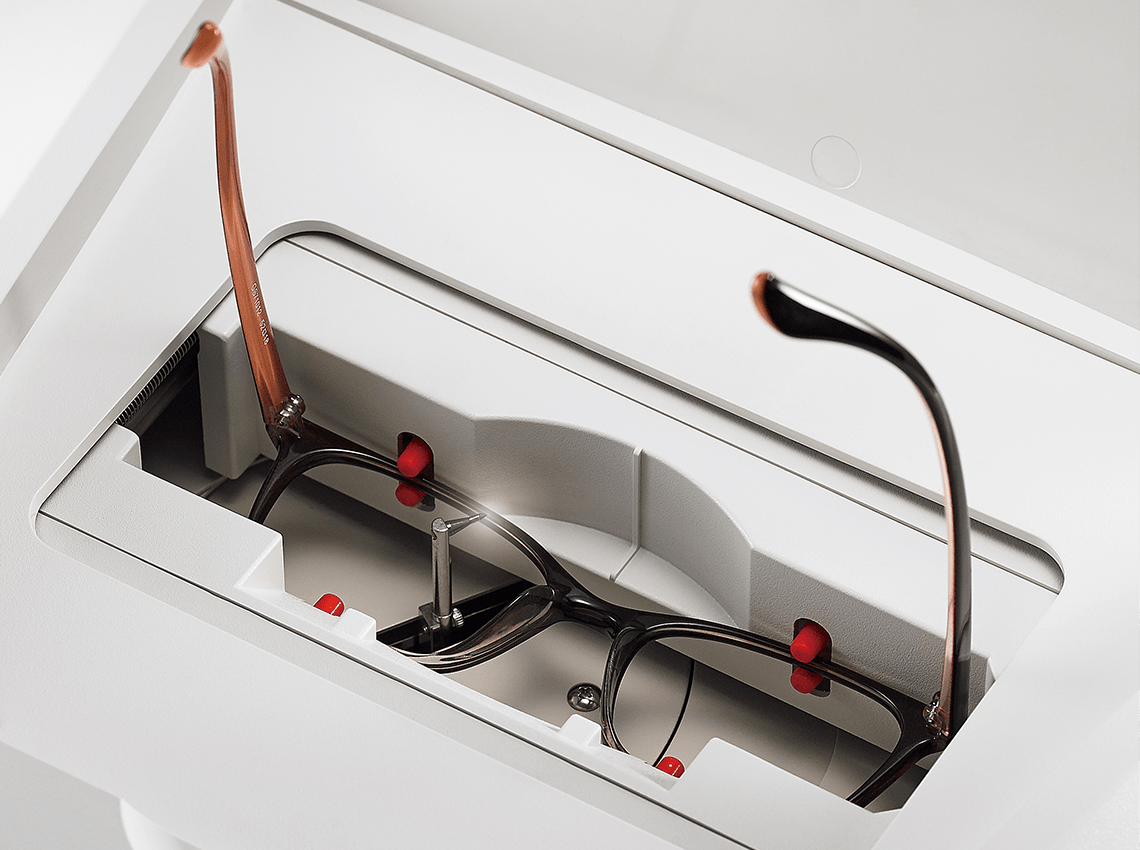

Reduced processing time with built-in tracer

The built-in tracer allows frame tracing during lens processing, reducing processing time and saving space

Video

Huvitz MEMBERS

If you want more ophthalmology & optometry content

join Huvitz Members

Specifications

1. Edger Specification

Lens Material

Plastic, Polycarbonate, High Index Plastic, Glass, Trivex

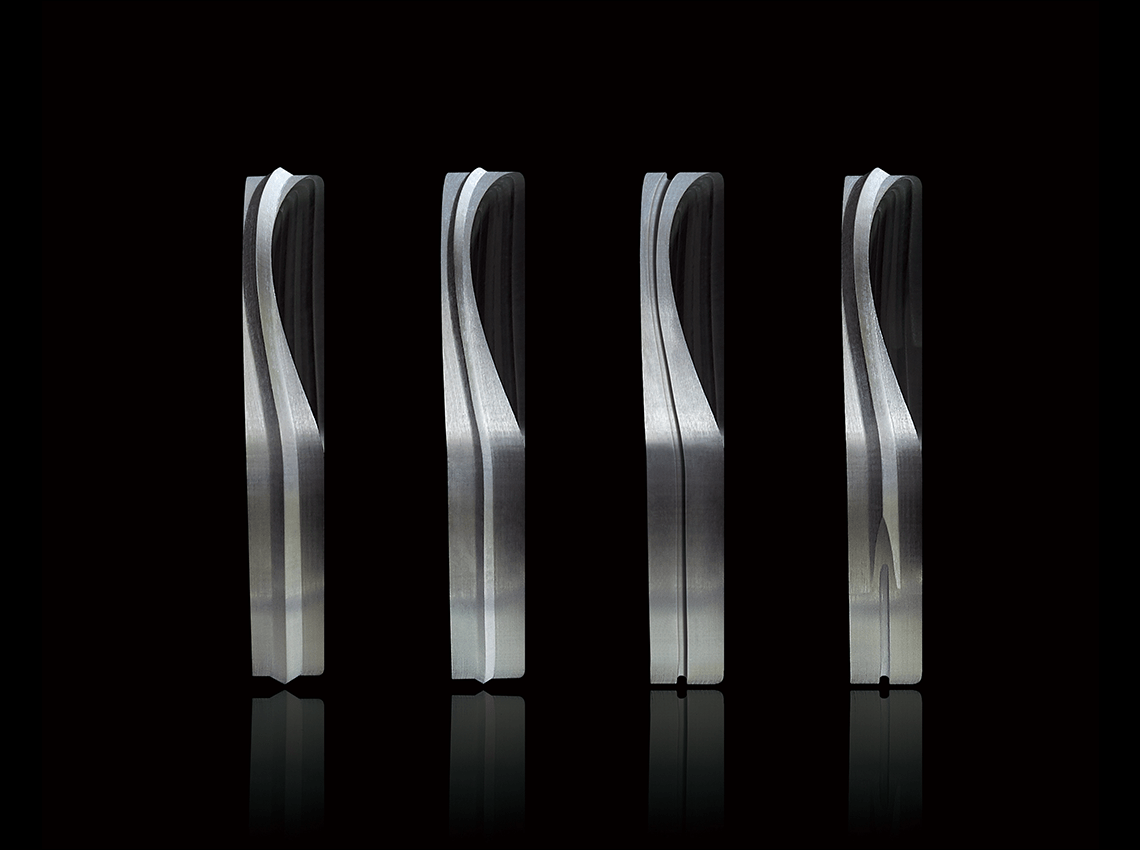

Wheel

Diameter 100mm, RPG Type

Edging Mode

Beveling (Normal / Partial / Mini Bevel)

Grooving (Normal / Partial / Hybrid / Dual Grooving)

Flat Edging

Safety Beveling

Polishing

*Auto/Manual position with 2D/3D simulation supported for beveling and grooving.

Functions

Job Manager, Digital Pattern, Retouch, Bevel / Groove Simulation, Shape Mirroring, Concave Shape

Utilities

Manual Edging Room Door(Hinged Door)

Edging Room Illumination

Single Side Feeling(Front, Rear)

SD Card Storage(Memory Included)

Display

9.7 inch Color TFT LCD(1024x768) with Touch Screen

Edging Size

Max : 90mm

Min :

Flat Edging : 18.5mm (without Safety Bevel) / 23.0mm (with Safety Bevel)

Bevel Edging : 20.0mm (without Safety Bevel) / 24.7mm (with Safety Bevel)

Dimensions

604(W) x 571(D) x 369(H)mm

Weight

47kg or Less(without Tracer Module)

Power Supply

AC 100~120V / AC 200~230V 50/60Hz

Power Consumption

1400W(110V), 1500W(220V)

2. Tracer Specification

Tracing Type

Automatic 3D Binocular Tracing

Tracing Mode

Auto, Semi-Auto

Tracing Size

Frame ø16.0~92.0mm, Pattern ø16.0~84.0mm

Frame Material

Metal, Hard Plastic, Soft Plastic

Data Processing

FPD, Frame Curve, Circumference, 3D Angle, Concave Shape

3. Product Types & System Configurations

Product (Types) / Voltage

Tracer

SBG

Class Wheel

HPE-410 /220V

O

O

O

HPE-410(NTR) / 220V

X

O

O

HPE-410 / 110V

O

O

O

HPE-410(NTR / NGL) / 110V

X

O

X(RPW)

* Specification and design are subject to change without notice.

Related Products

FAQ

Q. What are the key features of the HPE-410 lens edger?

A. The HPE-410 is a standard lens edger equipped with all the essential functions required for lens processing, featuring a built-in tracer. The integrated tracer allows frame tracing to be performed simultaneously with processing, reducing overall working time and enabling efficient use of installation space. It also supports 6 bevel types and 4 grooving options, and through 2D and 3D simulation, it automatically calculates the optimal processing position based on lens type, thickness, and frame shape, ensuring more accurate results.

Q. What lens materials and frames is the HPE-410 suitable for?

A. The HPE-410 can reliably process a wide range of lens materials, including plastic, polycarbonate, and high-index plastic. It is also compatible with various frame types such as metal, hard plastic, and soft plastic frames, making it well suited for general optical dispensing environments.

Q. What advantages does the built-in tracer provide on the HPE-410?

A. The greatest advantage of the built-in tracer is that processing and frame tracing can be performed simultaneously, significantly improving work efficiency. Since no separate tracer installation is required, space can be saved, and completing both tasks in a single workflow helps reduce processing time and optimize overall work flow.

Q. How is the user interface of the HPE-410 designed?

A. The HPE-410 features an intuitive user interface designed for ease of use, even for beginners. The front LCD screen allows users to view processing modes, bevel, and grooving settings at a glance, while the simple button-based control system enables fast and accurate lens processing.

Q. Is maintenance and management of the HPE-410 easy?

A. The HPE-410 can be used reliably through regular cleaning, replacement of consumables (such as grinding wheels and water filters), and routine software checks. If any issues occur during operation, dedicated technical support is available through phone consultation, remote support, or on-site service.